Sorry for the inconvenience.

Search again what you are looking for

SOXLANA offers you everything you need. Be satisfied first and then pay later.

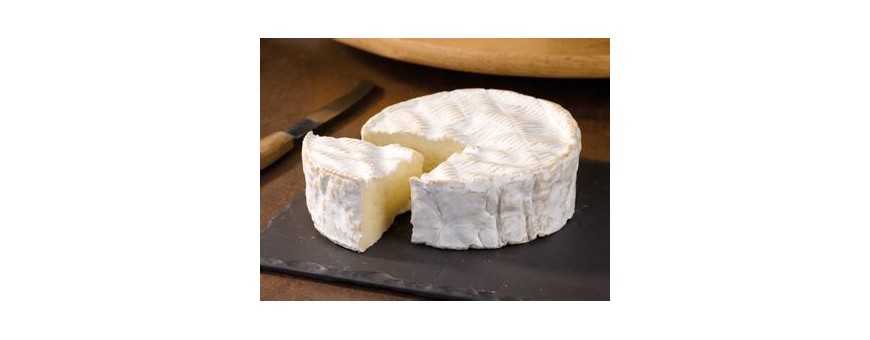

Camembert is a generic name which generally designates a soft cheese with a bloomy rind. Commercially, this appellation of Norman origin is not subject to any protection and is used for cheeses that sometimes have little to do with the original Camembert. In some regions of France, Camembert is called “claquos”, “calendos” or “camembos” or cadendos or cadenli or cadenil and in the Jura, it is called Comté coulant.

To distinguish itself from this multitude of cheeses called "camembert" by their manufacturers, the Norman agricultural production chain of the original camembert has applied for and obtained the registration as PDO, protection of the European Union, of the designation of origin. "Camembert de Normandie". The production of milk and its transformation into cheese are ensured only by this sector made up of farmers, producers and processors who respect the specifications attached to this official label.

Origins

There were cheeses in this region long before the birth of the famous Norman Marie Harel, in 1761. From 1554 and 1569, the cheese of the Pays d'Auge is mentioned. In 1708, Thomas Corneille mentioned Camembert cheese in a treatise on geography. Since the 18th century, Camembert has become a benchmark. According to Pierre Androuët, this cream cheese made from skimmed and drained curdled milk has been transformed by the secret of making brie cheese and its economic development is linked to the proximity of fashionable seaside resorts: the cheese found there a clientele of tourists who introduced him to Paris. According to legend, historically not very credible, the history of cheese begins in October 1791, when Marie Harel, a resident of Camembert, helps the refractory Alençonnais priest Charles-Jean Bonvoust to escape the Republicans. This priest, allegedly from Brie, would then have thanked her by revealing to her the secret of making Briard cheese. Marie Harel (II), the daughter of Marie Harel (I) and her husband Thomas Paynel, gradually increased the production of this new cheese. Napoleon III, during a stay in Argentan, would have tasted it, appreciated it and had it delivered to his Tuileries palace in Paris. This is how the fortune of Camembert would have started.

Element of the military ration

The inclusion of a portion of Camembert in the military ration during the First World War also contributes to the distribution of the product.

The battle of raw milk

The emergence of food health crises involving raw or pasteurized milk are always possible. They can strongly affect producers and processors. There is a divergence of dominant points of view on the concepts of “health risks” and “quality” between France and certain Anglo-Saxon countries (the United States, in particular). Raw milk is perceived as a source of risk in some countries, and as a guarantee of quality in others; In 2007, the Lactalis group and the Isigny-Sainte-Mère Cooperative, the two largest manufacturers of Camembert in Normandy, then producing 90% of the volume of this Protected Designation of Origin, wished "temporarily" to abandon the latter for no have more to respect the constraints, for health reasons according to these companies. This would have resulted in a fall in sales from 6,500 tonnes in 2007 to 4,500 tonnes between 2007 and the end of 2008. Not ceding to the pressure of the 2 industrial processors, the Syndicat des Manufacturers de Camembert de Normandie refused to modify its specifications. charges. The Isigny-Sainte-Mère Cooperative has finally relaunched the production of Camembert de Normandie, while maintaining the production of "generic camembert" under its Le Médaillon brand, made from microfiltered milk.

The early 2000s saw the total disappearance of modest peasant productions of Camembert from Normandy.

In 2019, three large farms are producing Camembert de Normandie marketed with the “farmer” label.

Manufacturing

Roasted Camembert and its accompaniments.

The milk is warmed to around 37 ° C then inoculated into leaven (lactic acid bacteria) before being renneted. Coagulation takes about 3/4 of an hour. The curd cheese is sliced into small cubes, using a curd slicer. Left to stand, the whey rises to the surface. It is drawn off by the cheese maker before the curd is placed in a mold. There, the draining continues and the mold gives its circular shape to the cheese. The cheese is turned over several times to drain evenly.

Once formed, the cheese is moved to the hamper where ripening begins. The temperature and the hygrometry are regulated in order to put the lactic ferments in the best conditions of development. After a few days a white felting appears.

Originally, the rind of Camembert was a greenish blue with red spots. With the Parisian public at the start of the 20th century preferring it to be whiter, the mold responsible for the coloring of Camembert was eradicated by Penicillium Candidum, another mold. Today Camembert is no longer produced from Penicillium camembertii but by mold created in vitro by the Institut Pasteur.

Image of cheese

Symbol of its aura with consumers, there are collectors of Camembert boxes, the tyrosemiophiles. Along with the baguette, he is an international symbol of France.

Search again what you are looking for

This website uses cookies. By continuing to browse the site, you accept our use of cookies. En savoir plus ici.